About Global Lift Used Forklifts Alaska

Global Lift Alaska - The following forklift classes describe the use and fuel option of each forklift. Certification is really necessary for each and every class of forklift that the operator will be using.

Class 1

These forklifts come with either pneumatic or cushion tires. Pneumatic tires are suggested for outdoor application in dry conditions. The cushion tired models are made for smooth, indoor surfaces. These are electrically powered vehicles that make use of industrial batteries, which make them suitable inside closed environments where the quality of air is a concern. Hoist functions and travel are controlled by transistor motor controllers. These are versatile units commonly used everywhere from the loading dock to the storage facility.

Class 2

This forklift is suggested for environments where narrow aisles have to be negotiated. They are effective at maximizing the use of storage space. Their unique design makes them perfect for small spaces and where speed is required.

Class 3

These battery-powered, hand-controlled models are intended for the operator to stand in front of the truck and operate the lift utilizing a steering tiller. The tiller has controls mounted on top and is moved laterally in order to maneuver the vehicle. The units which have smaller capacity use industrial batteries.

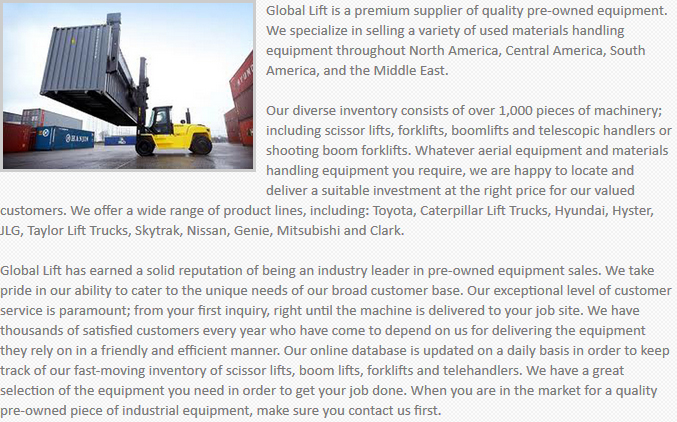

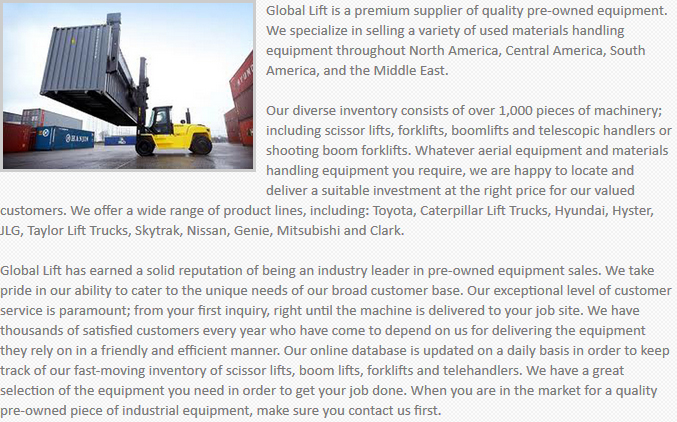

Forklifts, also called industrial-powered lift trucks, allow operators to move and carry bulky or heavy objects easily and efficiently. They are an important tool utilized for moving merchandise and cargo through the logistical supply chain. Forklifts are either electrically powered, or diesel- or gas-powered. Gas-powered types run on diesel, liquid propane gas or gasoline. Training in the safe and proper use of forklifts, such as correct fueling methods, is very vital for all forklift operators.

There are various kinds of forklifts meant for various uses and environments. Forklift types consist of narrow aisle, side loader, sit-down units and reach trucks. Your selection of a forklift depends on the particular tasks that would be carried out.

Each and every year, about 100 individuals are killed in accidents which are related to forklifts within the United States. Many more people receive serious injuries in forklift mishaps. Correct safety training is required to reduce the risk of accident.

Forklifts are powered either by diesel, battery, gasoline or propane. Each and every different kind is suitable to a different workplace setting.

So as to carry heavy supplies, metal forks, that come with forklifts are utilized. Possible attachments include buckets, clamps and hoists.

In warehouse settings, forklifts have to maneuver in really narrow aisles and have a tight turning radius. There are particular kinds of forklift intended for this kind of environment. Narrow aisle forklifts enable a warehouse or distribution center to dedicate a lot more space to merchandise.

Powered lift trucks referred to as forklifts are utilized in almost every industry to move heavy products and supplies. The forklift is a very durable and dependable equipment which has become essential tools in many warehouse and construction settings. Forklift units differ depending on the type of fuel which is used to power the lift truck and the kind of work setting.

Electric forklifts are recommended for work sites that have limited ventilation since they make no exhaust fumes and are fairly quiet. They are designed to be powered by industrial-strength, large batteries. Since the electric forklift batteries must be charging, the worksite must have a charging station. The batteries are tough and can be re-charged up to one thousand five hundred times before they have to be replaced. The charging station must be located in a ventilated area and include an acid spill kit and an emergency eyewash station.

Forklifts powered by liquid propane have some benefits over electric and diesel powered machinery making them fairly common in industrial and warehouse settings. Propane engines are a lot cleaner compared to diesel-powered units. There is no down time needed to recharge an industrial battery, and the cost of electricity is more than the cost of propane. A forklift propane tank can be easily and quickly refueled by changing out the empty tank with a full tank. Usually an off-site supplier refills the empty tank, making refueling very efficient and safe.

For outdoor applications and rough terrain, the gas and diesel forklifts are the machines of choice. These machines are quite common on construction sites and in lumber yards. Their disadvantages include relatively high maintenance requirements, odorous exhaust and relatively high fuel costs. Their benefits comprise a longer lifespan compared to other units and reliability in tough conditions. Diesel and gasoline units must be refueled at a supply station on site which meets safety and health regulations.

Contact Info

Fax: 1-888-029-0202

Fax: 1-888-029-0202

Questions or Comments